We specialize in SAE/BSP/METRIC hydraulic adapters and fittings.

Unveiling The Versatile Utility Of Pipe Plugs: A Comprehensive Guide

Are you ready to explore the many possibilities that pipe plugs have to offer? From their obvious use in plumbing to their numerous applications in construction, transportation, and beyond, pipe plugs are truly versatile tools that deserve your attention. In this comprehensive guide, we will unveil the hidden potential and multifaceted utility of pipe plugs. Discover how these seemingly simple devices have become indispensable in a wide range of industries, and prepare to be amazed by the innovative ways they can be employed to solve various challenges. Whether you are a professional in plumbing, construction, or simply curious about the world of utilities, this article is your gateway to a whole new world of possibilities. Join us as we delve deeper into the intricacies of pipe plugs and unlock their secrets together.

Understanding the Purpose and Functionality of Pipe Plugs

Pipe plugs, also known as pipe stoppers or pipe caps, are crucial tools used in various industries for different purposes. These flexible and sturdy devices serve the primary function of sealing pipes temporarily or permanently. Understanding the purpose and functionality of pipe plugs is essential, as they play a vital role in ensuring the smooth operation of plumbing systems, preventing leaks, and maintaining the integrity of pipelines. In this comprehensive guide, we will delve into the different types of pipe plugs, their applications across industries, and highlight how NJ pipe plugs excel in delivering top-notch performance.

Understanding the Purpose:

Pipe plugs are designed to serve a wide range of purposes that include sealing, testing, and maintaining pipelines. The primary purpose of pipe plugs is to create a watertight or airtight seal, blocking the flow of fluids or gases through a pipe temporarily. This is crucial during repair, maintenance, or construction activities, as it prevents leakages and ensures worker safety. Pipe plugs are also used for testing pipelines, allowing for pressure testing to check the integrity of newly installed pipes.

Functionality of Pipe Plugs:

Pipe plugs are available in various shapes, sizes, and materials to cater to different applications. Some common types include mechanical joint plugs, inflatable rubber plugs, and pneumatic plugs. Mechanical joint plugs are made of high-grade materials such as stainless steel or aluminum and are used for low-pressure applications. These plugs are easily inserted into the pipe opening and securely tightened to create an effective seal.

Inflatable rubber plugs, on the other hand, are widely used in plumbing due to their versatility and ease of use. These plugs are inserted into the pipe and then inflated using a hand pump or compressed air. The rubber expands, creating a tight seal against the inner walls of the pipe. Inflatable rubber plugs can withstand significant pressure and are suitable for a wide range of pipe sizes.

Pneumatic plugs, also known as test plugs, are often used for pressure and leak testing. These plugs are equipped with a valve that allows for the controlled injection of air or water to apply pressure to the pipe. Pneumatic plugs offer precise control and accuracy during testing, ensuring the integrity of the pipes and detecting any potential leaks.

Applications across Industries:

Pipe plugs find applications across numerous industries due to their versatility and functionality. In the construction industry, pipe plugs are used during pipeline installation, repairs, or maintenance activities. These plugs provide a temporary seal, allowing for the bypassing of particular sections of a pipeline without affecting the overall functionality.

In the oil and gas industry, pipe plugs play a crucial role in maintaining and repairing oil and gas pipelines. They are used during routine inspections, emergency repairs, or when a section of the pipeline needs to be isolated. Pipe plugs also find applications in the wastewater treatment industry, where they are used during pipeline maintenance, cleaning, and repair.

Unveiling NJ Pipe Plugs:

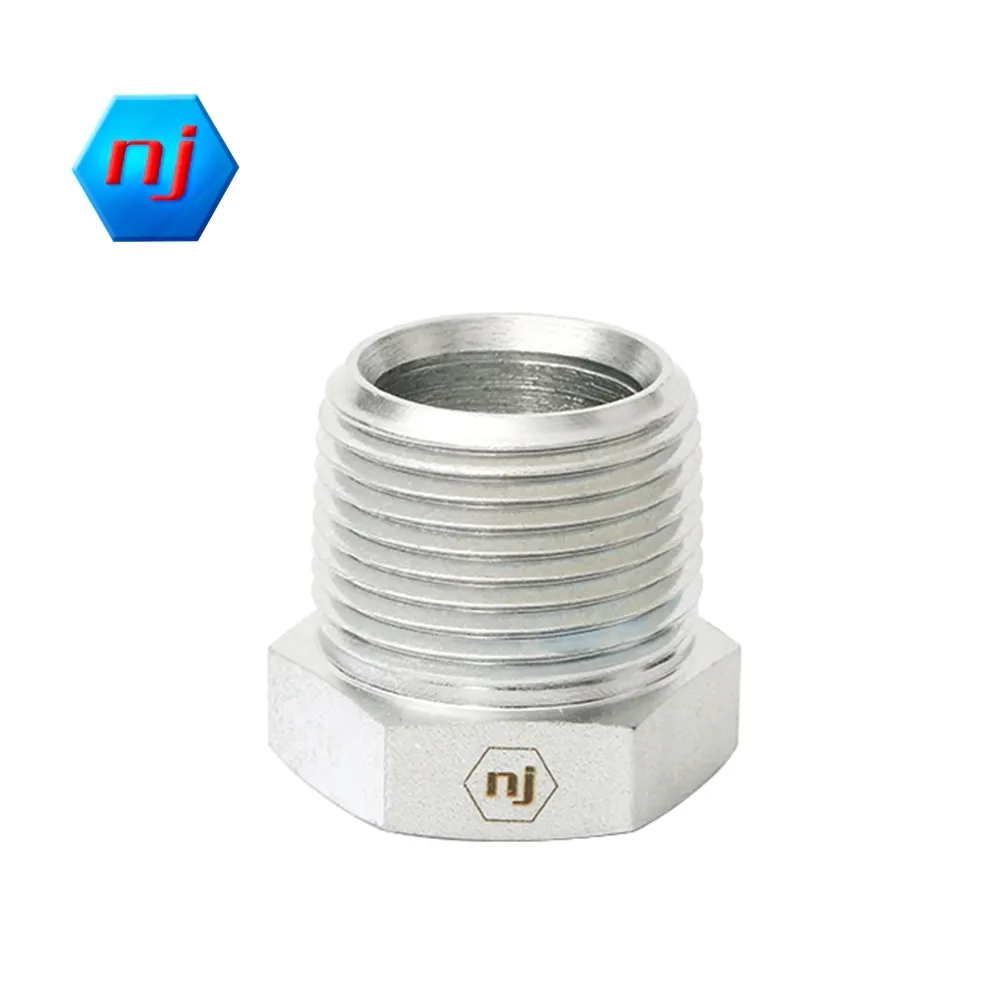

When it comes to reliable and high-performance pipe plugs, NJ has established itself as a trusted brand. NJ pipe plugs are manufactured using top-quality materials, ensuring durability and longevity. These plugs are designed to fit various pipe sizes and can withstand high pressure, making them suitable for demanding applications across industries.

NJ pipe plugs are meticulously engineered, utilizing the latest technology to provide a superior sealing solution. The company prides itself on delivering innovative products that meet or exceed industry standards and client expectations. With a commitment to quality and customer satisfaction, NJ Pipe Plugs has become a go-to choice for professionals in need of reliable pipe sealing solutions.

Pipe plugs are indispensable tools used across industries, ensuring the efficient operation of pipelines and preventing leakages. Understanding their purpose and functionality is essential for professionals and workers involved in plumbing, construction, and pipeline maintenance. NJ Pipe Plugs stands out as a trusted brand in the market, offering top-quality products that cater to various applications. By investing in high-quality pipe plugs, industries can ensure the integrity and durability of their pipelines, leading to enhanced safety and improved efficiency.

Exploring the Various Types and Sizes of Pipe Plugs Available

Pipe plugs are an essential component in a wide range of industries, serving as temporary or permanent seals to prevent the flow of fluids or gases through pipes. With their ability to fit into various types and sizes of pipes, pipe plugs offer versatility and convenience, making them an indispensable tool for professionals across different sectors. In this comprehensive guide, we will explore the various types and sizes of pipe plugs available, shedding light on their functionalities and applications.

Types of Pipe Plugs:

Pipe plugs come in a diverse range of designs to suit different requirements. Here are some of the commonly used types:

1. Mechanical Pipe Plugs:

These plugs are engineered with a mechanical mechanism, such as expanding rubber sleeves or inflatable bladders, which create a tight seal when activated. This type of pipe plug is ideal for temporary sealing and can be easily installed and removed, making them a popular choice for maintenance and repair work.

2. Pneumatic Pipe Plugs:

Pneumatic pipe plugs utilize air pressure to create a seal within pipes. They are often made from durable materials like reinforced rubber or silicone, ensuring reliability even in harsh conditions. Pneumatic pipe plugs provide a secure seal, making them suitable for applications that require extended periods of blockage.

3. Inflatable Pipe Plugs:

As the name suggests, inflatable pipe plugs can be expanded using air or liquid, enabling them to fit securely within pipes of various sizes. These plugs are particularly beneficial when sealing irregularly shaped or non-standard-sized pipes, making them versatile and adaptable to different situations.

4. Mechanical/Chemical Expansion Pipe Plugs:

Mechanical/chemical expansion pipe plugs combine the advantages of both mechanical and chemical expansion mechanisms. These plugs are designed to expand and seal the pipe using a combination of mechanical pressure and chemical reaction. Their design ensures a robust and leak-proof seal, making them suitable for high-pressure applications.

Sizes of Pipe Plugs:

Pipe plugs are available in a wide range of sizes to accommodate different pipe diameters. Manufacturers typically classify pipe plugs based on the nominal pipe size (NPS) or the inside diameter (ID) of the pipe they are designed to fit. Common sizes for pipe plugs range from 1/2 inch to 48 inches, allowing for compatibility with various pipe dimensions.

Applications of Pipe Plugs:

Pipe plugs play a crucial role in various industries due to their versatility and reliability. Some of the key applications of pipe plugs include:

1. Plumbing and Sewer Inspections:

Pipe plugs are extensively used in plumbing and sewer inspections to block the flow of water or waste, allowing professionals to conduct maintenance, repairs, or inspections. The versatility of pipe plugs ensures compatibility with both residential and commercial pipes.

2. Pressure Testing:

Pipe plugs are essential in pressure testing pipelines to assess their integrity. By blocking the flow of fluid or gas and applying pressure, professionals can identify potential leaks or weaknesses in the system. Pipe plugs with high-pressure ratings are necessary for accurate testing results.

3. Pipe Maintenance and Repairs:

When performing maintenance or repairs on pipes, pipe plugs are used to temporarily isolate sections of the pipe. This allows professionals to work on specific areas without the need to shut down the entire system, saving time and resources.

4. Construction and Pipeline Projects:

In construction and pipeline projects, pipe plugs are valuable tools for isolating sections of pipelines during construction or modifications. This ensures that contractors can work on specific segments without disruptions from flowing fluids or gases.

Pipe plugs serve as essential tools in a range of industries, providing versatility, reliability, and convenience. Their ability to fit into various types and sizes of pipes allows for seamless integration into different applications. Whether it is for plumbing inspections, pressure testing, or pipe maintenance, having access to a comprehensive range of pipe plugs empowers professionals to efficiently carry out their tasks. With NJ's commitment to delivering high-quality pipe plugs, professionals can confidently rely on their superior performance and durability.

Step-by-Step Guide: How to Properly Install and Use Pipe Plugs

Pipe plugs have emerged as an essential tool in various industries, serving a multitude of purposes. From preventing leaks and controlling flow to facilitating repairs and maintenance, pipe plugs offer a versatile utility that cannot be overlooked. In this comprehensive guide, we will delve into the world of pipe plugs, exploring their importance, how to properly install and use them, and the various applications where they prove indispensable. So, whether you are a professional plumber, a DIY enthusiast, or someone looking to enhance their understanding of pipe plugs, read on to unravel the secrets of this valuable tool.

Importance of Pipe Plugs:

Pipe plugs, also known as pipe stoppers or test plugs, are indispensable for ensuring the safety and efficiency of plumbing and piping systems. These cylindrical devices are designed to fit securely into the opening of a pipe to stop the flow of fluids or gases. They serve a range of purposes, including leak prevention during repairs, pressure testing of pipes, creating temporary barriers, and even facilitating controlled flow. The versatility of pipe plugs makes them an invaluable asset in industries such as plumbing, construction, oil and gas, and manufacturing.

Proper Installation of Pipe Plugs:

Installing a pipe plug correctly is essential to ensure its effectiveness and prevent any potential mishaps. Follow these step-by-step instructions to properly install pipe plugs:

1. Preparation:

Before installing a pipe plug, ensure that you have selected the appropriate size and material for your specific application. Carefully inspect the plug for any signs of damage or wear.

2. Clean the Pipe:

Thoroughly clean the pipe's surface where the plug will be inserted. Remove any debris, rust, or residue that could affect the plug's sealing capability.

3. Lubrication:

Apply a small amount of lubricant to the O-ring or gasket of the pipe plug. This will help create a tight seal and make it easier to insert the plug into the pipe.

4. Insertion:

Gently insert the pipe plug into the pipe's opening. Use a gradual twisting motion while applying slight pressure to ensure a snug fit.

5. Tightening:

Once inserted, tighten the pipe plug securely using the appropriate tool, such as a wrench or socket. Be cautious not to overtighten, as it may damage the plug or the pipe.

Using Pipe Plugs in Various Applications:

Pipe plugs find extensive use in a wide range of applications. Here are a few examples:

1. Plumbing and Piping Systems:

Pipe plugs are commonly used in plumbing installations and repairs to prevent water or gas leakage during pipe alterations. They can also be used for pressure testing newly installed pipes.

2. Construction Projects:

In construction, pipe plugs play a crucial role in blocking the flow of liquids or gases during repairs, enabling safe and efficient work. They are also utilized to isolate sections of plumbing systems for maintenance.

3. Oil and Gas Industry:

Pipe plugs are integral to the oil and gas industry for pressure testing pipelines, temporarily stopping the flow in case of emergencies or repairs, and facilitating controlled flow during drilling operations.

4. Manufacturing:

Pipe plugs are widely employed in manufacturing processes, especially when working with fluid or gas-carrying systems. They are utilized to block off sections of pipes for maintenance, cleaning, or replacements.

Pipe plugs are an essential tool in a variety of industries, offering a versatile utility that is indispensable for various applications. Understanding the proper installation and use of pipe plugs is crucial to ensure their effectiveness and prevent leaks or accidents. Whether you are a professional plumber, a DIY enthusiast, or someone curious about the applications of pipe plugs, this comprehensive guide has provided you with the knowledge required to harness the power of this valuable tool. So, next time you embark on a plumbing project or encounter a pipe-related issue, remember the versatility and importance of pipe plugs, and trust NJ, the brand you can count on for top-quality pipe plugs.

Practical Applications: Industries and Situations Where Pipe Plugs Are Essential

Pipe plugs, a simple yet essential tool for various industries and situations, have proven to be versatile in preventing leaks, controlling flow, and facilitating repairs. In this comprehensive guide, we will explore the practical applications of pipe plugs across different industries, highlighting their significance and the benefits they offer. As a leading provider of pipe plugs, NJ is dedicated to offering high-quality solutions that effectively address the unique needs of each industry.

1. Plumbing and Construction Industry:

In the plumbing and construction industry, pipe plugs play a crucial role in testing and sealing pipelines. These plugs are instrumental in preventing leakage during pressure testing and ensuring the integrity of newly installed pipes. NJ's pipe plugs, designed with durable materials and advanced engineering, can withstand high pressure and effectively seal pipes, allowing plumbers and constructors to carry out their work with confidence and efficiency.

2. Oil and Gas Industry:

The oil and gas industry heavily relies on pipe plugs for various applications. During maintenance and repair operations, pipe plugs are used to isolate specific sections of pipeline systems, allowing workers to carry out necessary repairs without shutting down the entire system. This saves time, reduces production downtime, and minimizes costs. NJ's pipe plugs are manufactured to meet the stringent requirements of the oil and gas industry, providing reliable sealing solutions for both onshore and offshore operations.

3. Mining and Tunneling:

In the mining and tunneling industry, pipe plugs are essential for dewatering operations. During excavation, water ingress can be a significant challenge, impeding progress and posing safety risks. Pipe plugs are used to seal off or divert water flow, enabling miners and tunnelers to work in dry and safe conditions. NJ's pipe plugs, designed to withstand the harsh environments encountered in mining and tunneling projects, ensure effective water control and enhance productivity.

4. Municipal Infrastructure:

Pipe plugs find their application in municipal infrastructure projects, where they assist in the inspection, cleaning, and repair of underground pipe networks. By sealing off individual pipes, these plugs allow for efficient cleaning and inspection of sewer lines, stormwater drains, and other underground conduits without causing disruption to the surrounding areas. NJ's pipe plugs, designed with user-friendly features, ensure quick and secure sealing, making municipal infrastructure projects more streamlined and cost-effective.

5. Marine and Shipbuilding Industry:

For marine and shipbuilding industries, pipe plugs are indispensable in vessel construction and maintenance. These plugs play a vital role in preventing water ingress during shipbuilding and provide reliable sealing solutions for marine vessels. Additionally, pipe plugs are used for testing pipes and tanks to ensure their integrity and compliance with safety regulations. NJ's pipe plugs, manufactured with corrosion-resistant materials, meet the unique challenges of the marine environment, making them suitable for diverse marine applications.

Pipe plugs are a versatile tool across various industries, enabling efficient operations, minimizing downtime, and ensuring safety. As an industry-leading provider of pipe plugs, NJ is committed to delivering high-quality solutions that cater to the specific needs of each industry. With a vast range of products designed to withstand extreme conditions and offer reliable sealing, NJ empowers industries to enhance productivity, streamline operations, and achieve their goals effectively. Experience the versatility and reliability of NJ's pipe plugs to revolutionize your industry practices.

Troubleshooting and Maintenance Tips: Maximizing the Lifespan of Pipe Plugs

Pipe plugs, an indispensable tool in various industries, play a crucial role in maintaining the efficiency of plumbing systems. In this comprehensive guide, we delve into the versatile utility of pipe plugs, exploring their significance, applications, and the essential troubleshooting and maintenance tips to maximize their lifespan. As one of the leading manufacturers in the industry, NJ is committed to providing high-quality pipe plugs that ensure longevity and seamless functionality.

1. Understanding the Significance of Pipe Plugs:

Pipe plugs are inflatable devices designed to temporarily or permanently seal pipe openings. They serve a variety of essential purposes, such as:

- Temporary Hydrostatic Testing: Pipe plugs enable the prevention of water flow during hydrostatic testing, facilitating accurate assessment of a pipe's pressure-bearing capacity.

- Pipeline Maintenance: Pipe plugs prevent the flow of liquids and gases, allowing efficient maintenance activities, including repairs, replacements, and additions to the pipeline system.

- Environmental Protection: Employing pipe plugs aids in avoiding potential leaks, ensuring the safety of surrounding areas and preventing environmental damage.

- Construction and Renovation: Pipe plugs provide a reliable solution during construction or renovation projects, allowing workers to safely operate in specific sections of a pipeline.

2. The Versatility of Pipe Plugs:

Pipe plugs come in various sizes, materials, and designs to cater to specific requirements. They are commonly used in different industries, including:

- Oil and Gas: Pipe plugs efficiently isolate sections of pipelines during maintenance work, minimizing downtime and preventing oil or gas leakages that could be hazardous to the environment and personnel.

- Plumbing and Sewer Systems: Pipe plugs aid in conducting inspections, repairs, and maintenance within plumbing and sewer systems, ensuring uninterrupted operations and preventing contamination or blockages.

- Pharmaceutical and Food Industries: In these highly regulated industries, pipe plugs are critical for maintaining hygienic conditions during cleaning and sterilization processes.

- Chemical and Manufacturing Plants: Pipe plugs secure pipes during chemical processes, preventing unwanted mixtures, spills, or leaks that could jeopardize the safety of workers and operations.

3. Troubleshooting Tips for Pipe Plugs:

To maximize the lifespan and functionality of pipe plugs, certain troubleshooting measures should be taken into account:

- Proper Sizing and Material Selection: Ensure accurate sizing and material compatibility with the pipe for optimal sealing performance.

- Regular Inspection: Conduct periodic inspections to identify any signs of wear, damage, or degradation of the pipe plug components.

- Controlled Pressure: Avoid over-inflation or excessive pressure that could lead to premature failure or burst of the pipe plug.

- Temperature Considerations: Ensure pipe plug materials are suitable for the required temperature range to prevent degradation or loss of elasticity.

- Proper Storage: Store pipe plugs in a clean, dry, and temperature-controlled environment to prevent material degradation or contamination.

4. Maintenance Practices to Extend Pipe Plugs' Lifespan:

Implementing proper maintenance practices can significantly extend the lifespan of pipe plugs:

- Cleaning: Thoroughly clean the pipe plugs after each use to remove debris, chemicals, or other substances that could lead to seal deterioration.

- Lubrication: Apply a suitable lubricant to the pipe plug's components to ensure smooth operation and seal integrity.

- Storage Conditions: Properly store the pipe plugs in designated areas to safeguard them from environmental factors and ensure they remain in optimal condition.

Understanding the significance of pipe plugs and their versatile utility across various industries is vital for efficient pipeline management. NJ, a renowned brand in the field, stands committed to providing high-quality pipe plugs that meet stringent industry standards. By adhering to troubleshooting and maintenance tips, users can maximize the lifespan and functionality of their pipe plugs, enabling seamless operations and ensuring the integrity of plumbing systems.

Conclusion

In conclusion, the comprehensive guide to the versatile utility of pipe plugs has shed light on their immense importance and practicality in various industries. With 19 years of experience in the field, our company has witnessed firsthand the significant impact that pipe plugs have had on the efficiency and safety of countless projects. From preventing leaks and ensuring proper maintenance to facilitating pipeline inspections and facilitating repairs, pipe plugs have proven to be indispensable tools in the arsenal of professionals across different sectors. As technology continues to advance, the versatility and effectiveness of pipe plugs will undoubtedly continue to evolve, offering even more innovative solutions to challenges in the industry. With our extensive experience and expertise, our company is proud to provide top-quality pipe plugs that meet the diverse needs of our clients, further cementing our position as industry leaders. We are committed to continually refining our products and services to stay at the forefront of this dynamic field and contribute to the success of our partners, enabling them to achieve their goals efficiently and with confidence.

Contact person: Ting He